Plate Heat Exchanger Rubber Gasket

Plate heat exchanger rubber gaskets play a critical role in ensuring efficient heat transfer, leak prevention, and operational safety. They are designed to seal the plates, guide fluid flow, and maintain separation between different media under pressure and temperature fluctuations. Proper gasket selection directly affects exchanger efficiency, service life, and maintenance cost.

1. Function of Rubber Gaskets in Plate Heat Exchangers

- Provide reliable sealing between adjacent heat exchanger plates

- Direct hot and cold fluids through designated flow channels

- Prevent cross-contamination between media

- Compensate for thermal expansion and plate deformation

Engineering Insight: Unlike static flat gaskets, plate heat exchanger gaskets must maintain elasticity under repeated thermal cycling and pressure changes.

2. Common Gasket Types for Plate Heat Exchangers

| Gasket Type | Installation Method | Features | Typical Applications |

|---|---|---|---|

| Clip-On Gasket | Mechanical fixing | Easy installation, reusable | HVAC, water systems |

| Glue-On Gasket | Adhesive bonding | Strong adhesion, stable positioning | Industrial processes |

| Snap-In Gasket | Groove locking | No adhesive required | Food & beverage, pharma |

3. Material Selection and Performance Characteristics

| Material | Temperature Range | Media Compatibility | Key Advantages |

|---|---|---|---|

| NBR | -30°C to +120°C | Oil, grease, water | Cost-effective, good elasticity |

| EPDM | -40°C to +150°C | Hot water, steam, glycol | Excellent heat and aging resistance |

| FKM (Viton) | -20°C to +200°C | Chemicals, oils | High temperature & chemical resistance |

| HNBR | -30°C to +150°C | Oil, refrigerants | Improved strength and durability |

Material Selection Note: EPDM is the most commonly used material for plate heat exchangers handling hot water and steam, while FKM is preferred for aggressive chemical environments.

4. Key Performance Tests

4.1 Compression Set

- Evaluates long-term sealing force retention

- Critical for continuous operation systems

4.2 Heat Aging Resistance

- Simulates long-term exposure to operating temperature

- Checks hardness and elasticity changes

4.3 Media Compatibility Testing

- Volume change and swelling tests

- Tensile retention after fluid exposure

5. Common Failure Modes and Causes

- Hardening or cracking due to thermal aging

- Loss of elasticity caused by high compression set

- Chemical attack from incompatible fluids

- Improper installation or uneven plate tightening

Best Practice: Regular inspection and timely replacement of gaskets prevent plate damage and unexpected downtime.

6. Maintenance and Replacement Recommendations

- Inspect gaskets during every plate opening

- Clean gasket grooves and plates before reassembly

- Avoid over-tightening to prevent excessive compression

- Store spare gaskets in cool, dry conditions

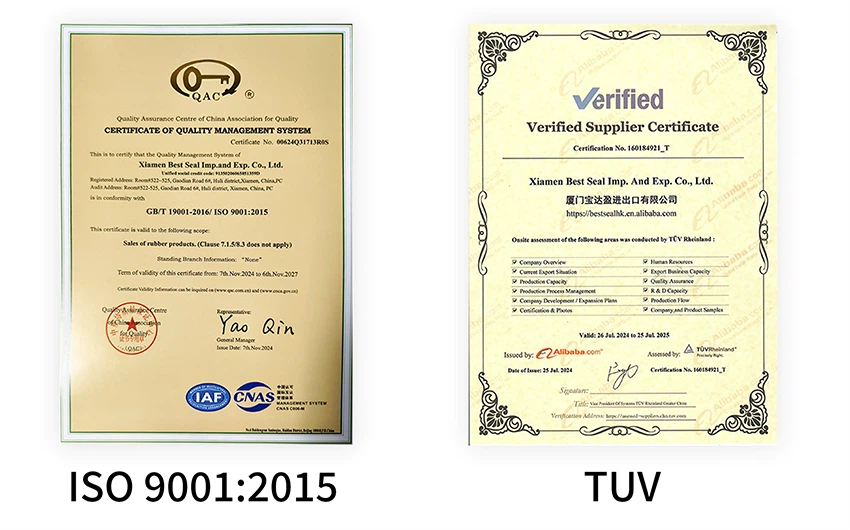

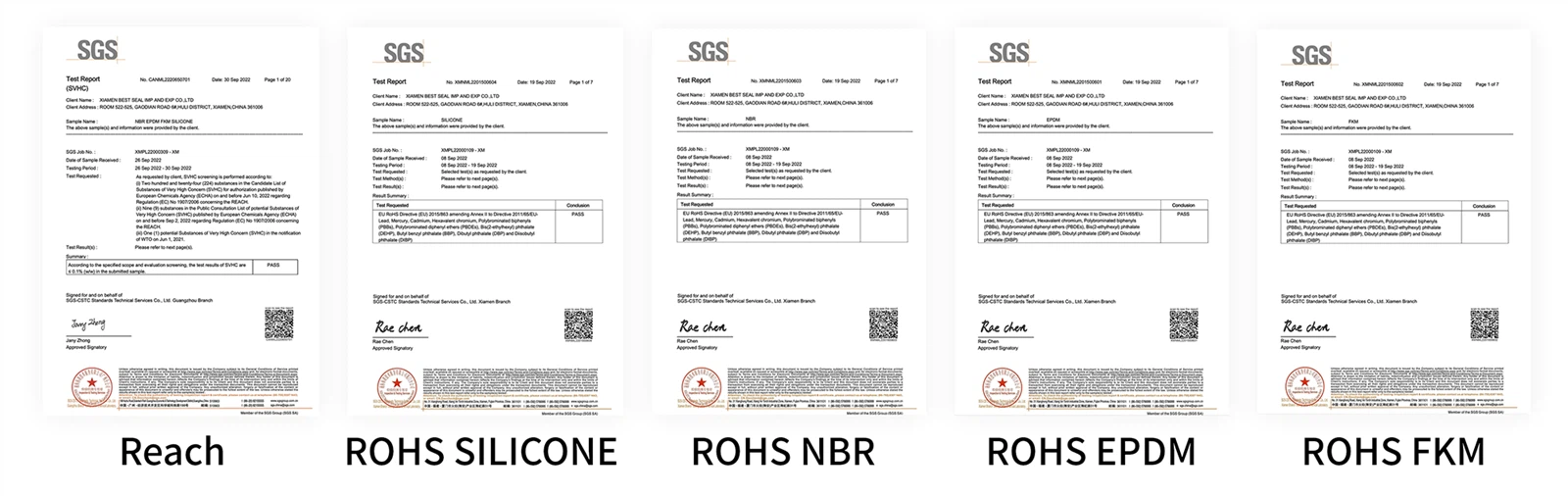

7.Quality & Certifications

Our rubber seal gaskets are manufactured under strict quality control and comply with major international standards, including ISO 9001, ASTM D2000, FDA, NSF, WRAS, RoHS, REACH, CE, and UL. All materials are tested to ensure consistent performance and long-term reliability.

Conclusion

Plate heat exchanger rubber gaskets are precision sealing components that directly influence heat exchanger efficiency and operational reliability. Selecting the correct material, structure, and performance level ensures stable sealing, reduced maintenance, and extended service life.

About Us

Best Seal supplies high-quality rubber gaskets for plate heat exchangers, supporting OEM and aftermarket requirements worldwide.

- Custom profiles and reverse engineering support

- Materials: EPDM, NBR, FKM, HNBR, special compounds

- Strict performance and aging testing

- Stable quality and fast delivery

Hot Tags: plate heat exchanger rubber gasket, China plate heat exchanger rubber gasket suppliers, manufacturers, factory